DESIGN NAME:

Argus

PRIMARY FUNCTION:

Biometric Camera

INSPIRATION:

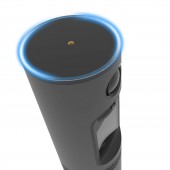

Argus is a nondescript mounted camera pillar that can ID 10 people per minute at 3 to 8 feet. It’s made for locations where laptops or alternate solutions won’t work, such as secure offices, airports, and checkpoints. Product layout was optimized to house a long zoom lens camera vertically and only move a mirror to give pan tilt functionality. This allowed a compact size and fast movement, while delivering high performance - groups could be identified at the same time! Initial designs moving a large large lens were deemed too dramatic and inertia presented problems. Styling was optimized for serious but minimal look, camouflaging high speed movements behind an opaque glass lens. Feedback is given to subjects with audio or visual signals allowing use without an operator present.

UNIQUE PROPERTIES / PROJECT DESCRIPTION:

Argus was created as a low cost alternative to more expensive biometric solutions or staffed checkpoints. The current auto-recognition systems are expensive and require multiple cameras around a portal where people pass. They also use high levels of IR light. Argus simplifies this with a single mounted camera system that can pan, tilt, and zoom at high speed to capture all people passing and aims less IR light only at a single person. A longer custom made low-light zoom lens & camera can be used because it is in a vertical orientation. This increases the capture range, even people in wheelchairs. Moving a lightweight mirror rather than heavy camera allows for faster movement and ability to ID multiple people faster. Cost was reduced using off the shelf hi-speed & hi-res cameras, arduino pcb, & servo motors. The cylindrical camera can be mounted in a variety of ways, adding flexibility to use scenarios.

OPERATION / FLOW / INTERACTION:

Argus first recognizes faces with a wide angle camera, calculates subject’s face location in 3d space, then sends pan/tilt/zoom instructions to lens abd mirror motors. Built in IR LEDs are aimed at eyes in wavelengths not visible to humans. The camera aims & focuses on each person’s eyes to capture high res iris images. Capture is at 75 frames/sec, ensuring several sharp images on even moving subjects. A 2nd camera captures face ID images. Matching happens on a connected PC in milliseconds, then audio or 360 degree LEDs to communicate status to subject.

One use scenario could be in airports when people line up to pass checkpoints. Argus can instruct them to walk forward and pause, where ID capture happens. Where they stand is flexible with the pan-tilt range, and small groups can step forward together. Once identified, people are asked to move forward or wait. Another scenario is a secure site. People passing are constantly verified to biometric profiles of authorized personnel. If non-authorized people are found, alert is sounded.

PROJECT DURATION AND LOCATION:

The project kicked off in Washington D.C., Minnesota, Austin TX and Bristol UK in Dec 2015. Design activities started in Washington and Bristol in Jun 2016. The initial main device low volume production was started in July 2017. Revisions and accessories were continued to be developed until the start of 2018.

|

PRODUCTION / REALIZATION TECHNOLOGY:

Our team approached this challenge by leveraging our previous biometric development experience - we knew we could integrate hi-spec off-the-shelf components to outperform more expensive systems for a fraction of the cost. Argus uses hi-res 75 frame/sec digital cameras, standard motors and arduino PCBs. For select non-standard components we designed bespoke lenses, mechanisms, and enclosures for our specific needs.The lens was custom designed for unique low-light use but high zoom, unique to us and not available commercially. Mechanisms were developed to pan, tilt,and zoom but also be optimized for CNC mfg. The outer housing uses standard PVC pipe as the outer structure with smaller parts that are inserted. The internal parts are part of the CNC mechanism or sheet metal, both greatly reducing cost. Thermal issues were solved with active and convective cooling.

SPECIFICATIONS / TECHNICAL PROPERTIES:

Argus was designed to be a compact, simple cylindrical form that could be mounted in a variety of ways (floor or ceiling mounted, free standing, or wall mounted). The overall design is tightly fit into the form, efficiently using the space. Different lens options can capture different view boxes, shown in product image.

Dimensions: 168.28mm/6.62 in Diameter x 749.31mm/29.5 in Height

Mounted Height: 1859.31mm/73.2 in

Weight: 16 Lbs / 6 Kg

Capture Speed: 1/10 second per person at 75fps

Capture Distances: 3ft to 8ft

Pan Range: 27 Degrees left or right pan (54 degrees total)

Tilt Range: 34 Degrees left or right pan (68 degrees total)

TAGS:

Biometric camera, Multi-modal, Camera, Iris Recognition, Facial recognition, Identity, Security, Argus, Corvus

RESEARCH ABSTRACT:

At the start of the project, we had a general idea of what performance spec we had to meet or exceed, based on market research of competitors. This included costs, installation complexity, identification methodology, and camera specs. The learnings helped us lay out our unique concept. Sales people researched use case scenarios first hand with clients, which was used for product architecture, features, appearance, and placement. Subject well-being was important, so consideration of their experience was a priority. During development look & feel concepts, physical prototypes, and CAD images were continually tested with them for function & aesthetics. Feedback was integrated into later design iterations.Ultimately working prototypes were tested and any performance or other issues were improved until initial manufacture.

CHALLENGE:

Our main challenge was to create a high performance biometric camera at a low price to compete with expensive current systems. We used our expertise to invent new ways of configuring off the shelf components in a bespoke design to outperform existing products. From the start we developed the housing to use inexpensive std materials if possible, such as PVC tube structure rather than moldings. Some components were custom fabricated, such as zoom lens & mechanisms.

A second goal was a serene external design to convey non-threatening seriousness of purpose. Early concepts had a large moving cylinder to “aim” camera at subjects. This created dramatic movement which was unnerving to people and also caused difficult to control inertia in the device. Our design change to a vertical camera/lens position allowed no visible movement to the subject, and a more compact overall size. Two color schemes, white and black, are available to fit device in different environments.

ADDED DATE:

2018-02-19 16:26:35

TEAM MEMBERS (6) :

Industrial Designer: Travis Baldwin, Program Manager: Bill Willis, Mechanical Engineer: Bill Haushalter, Optical Engineer: Steve Eckhardt, Integration Manager: Jeff Kormanec and

IMAGE CREDITS:

Image #No 1-5 : Photographer Bill Haushalter, Argus prototype photo shoot, 2016-2017.

Image #No 1-5 : Designer Travis Baldwin, Argus Digital Prototype Imaging 2016-2017.

|