DESIGN NAME:

Plastidobe

PRIMARY FUNCTION:

Ecological Housing

INSPIRATION:

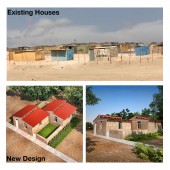

A historic flooding in Peru left an estimated of 700,000 people homeless. Concerned about this we made a home that is ecological, sustainable, safe, easy to assemble and is not expensive. With this in mind we decided to do research on ways of joinery so that no glue was required, materials so that it is sustainable for the earth, climatological conditions that may play against a rural house and structure both for packaging/transportation and shape, gathering inspiration from Incan architecture.

UNIQUE PROPERTIES / PROJECT DESCRIPTION:

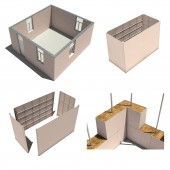

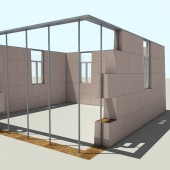

Each module consists of 4 plastic plaques gathered by pressure on the corners (male-female system), making for easy transportation, packaging and assembly. Recycled plastic is used to assemble this lightweight box that will contain wet earth in order to create a solid earth trapezoidal block that is acoustic and water resistant. Resistance and rigidity is not only achieved thanks to the ribbed surface and trapezoidal shape, but also because alfalfa root is used in-between the walls, making the house extremely resistant.

OPERATION / FLOW / INTERACTION:

Due to its size and weight, this house is easy to transport. Once the material arrives it is easy to assemble. This is family erected and just one technician may be needed to finish the construction. For every block jointed together, earth is filled. Once the height is achieved, the metal ceiling is applied. An alfalfa root is planted in the desired spots in between the walls. This will eventually grow and reinforce the house. Desired quantities of pasture are applied on top of the house. Doors and windows are optionally installed with the usual screw system.

PROJECT DURATION AND LOCATION:

This project was started in January 2017 in Lima, Perú.

FITS BEST INTO CATEGORY:

Social Design

|

PRODUCTION / REALIZATION TECHNOLOGY:

The structural ribbed plaques are created by injection molding from recycled high-density polyethylene bottles or polyethylene terephthalate bottles. A galvanized metal structure is necessary for the ceiling, which is later covered with pasture, serving as thermic insulator. Moisturized dirt lays between the plastic structures, in addition to that an alfalfa root grows inside the wall for structural reinforcement. Alfalfa roots grow up to 25 feet, these serve as columns that assure the house is connected to the ground, giving it unprecedented strength and stability.

SPECIFICATIONS / TECHNICAL PROPERTIES:

Packaging: A 57 cm x 82 cm. x 19 cm cardboard box fits 3 modules of 80 cm. X 40 cm.

Module typology and dimensions:

Basic Module: 800 mm. (long) X 400 mm. (wide) X 550 mm. (tall)

Medium Module: 400 mm. (long) x 400 mm. (wide) x 550 mm. (tall)

“L” Module: 1200 mm. (long) x 800 mm. (wide) x 550 mm. (tall)

TAGS:

House, Durable, Weatherproof, Eco-Friendly, Sustainable, Construction, Self-Assembly, Affordable Housing

RESEARCH ABSTRACT:

For this project we started by understanding the issues regarding houses in Peru right now. Taking a trip to Cuzco, Tacna, Lima (specially the non-centric parts of these cities) was part of our research to fully understand and see the situation in which people are living. Also studying the natural phenomenon such as climate or frequency of earthquakes and harsh situations it creates against those houses gave us a general view of the problem we had to solve. Making our solution eco-friendly at the forefront of our design that's why we did research on recycled plastics and possibilities with this material. This included suppliers to know price estimates since we wanted to make the house affordable. We also researched on ancient Peruvian design and shapes Incas used to create solid structures that have survived up until this time. This research included visits to Saksaywaman citadel, Machu Picchu or Tambomachay archeological spots. Finally we did a study on roots and how they could help us achieve structure if they served as a column in the wall. The study revealed the alfalfa root was perfect for this since it takes between 6 months and 2 years for roots to reach 3 meters deep. This was key because by incorporating alfalfa root into the design turns this project into the first housing structure that uses the roots of a plant to stiffen the house internal structure and reinforce it.

CHALLENGE:

The hardest part of developing a design for a house that is eco-friendly as well resistant to all the climatological adversities, price and ease of construction was definitely researching the materials that would help fulfill this vision. The series of materials and design decisions made work altogether as an orchestra that creates no adversities but rather advantages, overcoming every challenge of this mission.

ADDED DATE:

2017-03-28 21:02:30

TEAM MEMBERS (7) :

Lead Designer and Architect: Abel Gómez-Morón, Designer and Editor: Harry Gómez-Morón, Architect: Giovanni Marttini Abarca, Architect: Carlos Huatuco Nancer, Architect: Martin Rodriguez Nobaru, Architect: Gustavo Santivañez Gálvez and Architect: Roxana Talavera

IMAGE CREDITS:

Image #4 : Architect Abel Gómez-Morón, 2017.

|