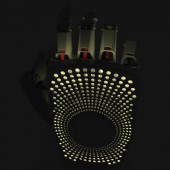

Illume 3D Printable Prosthetic by Cliff Shin |

Home > Winners > #48324 |

|

|

||||

| DESIGN DETAILS | |||||

| DESIGN NAME: Illume PRIMARY FUNCTION: 3D Printable Prosthetic INSPIRATION: There are 11.4 million people with hand amputations in the world, 80% of which come from developing countries. We are developing advanced, neutrally controlled prosthetic limbs, the first with sensory feedback, that can be produced for less than $1000. Patients who wear prosthetic hand typically have stigma and are emotionally unstable. When patient receive a new prosthetic hand, the patient will receive a ring that will fit in the fourth finger from the prosthetic hand. The patient will have si UNIQUE PROPERTIES / PROJECT DESCRIPTION: It is a 3D printable prosthetic hand. All parts were designed to be put together in two piece assemblies. Only one part would need to be attached at a time during assembly. This avoided complex processes requiring two hands. A four-bar linkage was used as a finger joint coupling mechanism to produce consistent movement and greater force at the fingertip than a purely tendon-based design. OPERATION / FLOW / INTERACTION: Upon wearing the device, users undergo a minute long training procedure that trains the microchip in the hand to recognize muscle signals from sensors placed on the user forearm. Once the hand associates the muscle signals with particular grasps, the user can just make the same muscle movements to control the hand to open, close, fine pinch, make a 3 finger grasp, or rest. The elegant, anthropomorphic design of the hand will increase user acceptance while maintaining high functionality. PROJECT DURATION AND LOCATION: Champaign, Illinois, USA |

PRODUCTION / REALIZATION TECHNOLOGY: The design of the hand incorporates five motors and worm gears to enable six degree-of-freedom articulation. Each digit of the hand can flex/extend, and the thumb additionally has the ability to oppose. The hand attaches to a socket which overlies the residual limb of the person with a transradial amputation. Electrodes embedded in the socket read muscle signals, which a machine learning algorithm decodes to actuate various grips in the hand, including hand open, close, fine pinch, 3 finger grasp, and rest. SPECIFICATIONS / TECHNICAL PROPERTIES: Height 220mm X Width 95mm X Depth 25mm TAGS: 3D Print, myoelectric, prosthetic hand, bionic RESEARCH ABSTRACT: People with transradial amputations who live in economically disadvantaged communities need a prosthetic hand that is not only functional but also affordable, easy to manufacture, and simple to maintain. We also realized that controlling force to hold a object is critical because there are many objects that are sensitive to pressure or impact like eggs or paper cups. Because of the holding pressure issue, we embedded pressure sensors on each fingers. Still, overall design is 3D printerable. CHALLENGE: It is a new approach to use micro motors and worm gears. The reason to use the motors and worms gears is to generate big torques. However, incorporating six micro motors and worms gears was a big challenge within tight space as well as placing a PCB board. Anther reason is to use the motors and worm gears is that all components are widely available on hobby stores online. Therefore, it will bring down overall cost to construct Illume. ADDED DATE: 2016-03-30 22:00:58 TEAM MEMBERS (6) : Cliff Shin, Timothy Bretl, Aadeel Akhtar, Patrick Slade, KyungYoon Choi and Michael Fatina IMAGE CREDITS: Cliff Shin |

||||

| Visit the following page to learn more: http://www.psyonic.co/#home-psyonic | |||||

| AWARD DETAILS | |

|

Illume 3d Printable Prosthetic by Cliff Shin is Winner in Cybernetics, Prosthesis and Implant Design Category, 2015 - 2016.· Read the interview with designer Cliff Shin for design Illume here.· Press Members: Login or Register to request an exclusive interview with Cliff Shin. · Click here to register inorder to view the profile and other works by Cliff Shin. |

| SOCIAL |

| + Add to Likes / Favorites | Send to My Email | Comment | Testimonials | View Press-Release | Press Kit |

Did you like Cliff Shin's Cybernetics Design?

You will most likely enjoy other award winning cybernetics design as well.

Click here to view more Award Winning Cybernetics Design.