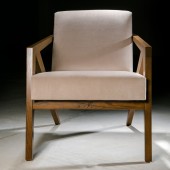

DESIGN NAME:

Geometric

PRIMARY FUNCTION:

Lounge Chair/Dining Chair

INSPIRATION:

This collection is inspired by the geometric structures of the industrial era (late nineteenth century), and is mixed with the silhouettes and the spirit of the 60's. It has a modernist zeal and a retro timeless touch, ideal for modern interior environments.

UNIQUE PROPERTIES / PROJECT DESCRIPTION:

The structure of the chair is both simple and edgy, relying solely on three axes, giving it a visual lightness. The tilting on the pieces provide an air of modernity and dynamism unique to this collection. The ergonomics of this armchair is perfect, it has the correct inclination of the seat and back, so you can relax and enjoy.

OPERATION / FLOW / INTERACTION:

The padding of the seat, despite being slender, has a progressive reaction so that it adapts to the weight and body shape of the person using it; it has four layers of foam of different densities and a flexible support webbing system to better accommodate ergonomically.

PROJECT DURATION AND LOCATION:

This project took 12 weeks from the first sketches to the final prototype for mass production, made in the laboratory and prototype design in Mérida, Yucatán, México.

FITS BEST INTO CATEGORY:

Furniture Design

|

PRODUCTION / REALIZATION TECHNOLOGY:

Built entirely of solid red oak wood oak. The joinery is made with mortise and tenon, using complex angles. This piece was designed to achieve the perfect fit and durability for everyday use, it was necessary to use high-tech machinery to produce this piece successfully.

The engineering of the seat and backrest allows a progressive cushioning thanks to the multiple layers of different densities of foam and elastic supports, delivering a smooth and enjoyable feeling. The upholstery was completely handmade, to offer more character and personality.

SPECIFICATIONS / TECHNICAL PROPERTIES:

656 mm W x 766 mm D x 742 mm H

TAGS:

Confortable seat, lounge chair, modern furniture, solid wood, 1960’s style, retro

RESEARCH ABSTRACT:

An extensive vector study of engineering was necessary to obtain the assemble system of the pieces without affecting the resistance. This resulted in a light and dynamic look that is seen in this piece, remaining robust and resistant.

CHALLENGE:

The retro was to develop a processing system and assembly based on the mortise and tenon joinery, that despite the sharp angles had a structure feasible to replicate in mass production with a good fit of vertices and unions.

ADDED DATE:

2015-06-30 00:27:24

TEAM MEMBERS (1) :

Gerardo Ríos

IMAGE CREDITS:

Ricardo López

|