Proteus Lighting by Bryan Liebowitz |

Home > Winners > #38598 |

|

|

||||

| DESIGN DETAILS | |||||

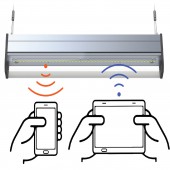

| DESIGN NAME: Proteus PRIMARY FUNCTION: Lighting INSPIRATION: As a lighting designer for many years, it has become increasingly obvious that the design of LED light sources in a luminaire is different to what has been used before. LEDs are actually electronic components that emit light and heat and only emit light in an arc of 180 degrees, rather than 360 degrees. This leads to light output being trapped and to operate at higher temperatures that lead to loss of source life. The initial intention was to find a way to free additional usable light and control temperature to give the longest life possible. UNIQUE PROPERTIES / PROJECT DESCRIPTION: This lighting and communications system consists of various LED lighting options for commercial, industrial, retail and architectural projects. These are added during factory production and then delivered to site for installation. Designed for future system expansion which currently includes VLC (visible light communications), security cameras, audio modules and moving LED text messaging. The extrusion can be up to 4 metres in length and joined end to end. OPERATION / FLOW / INTERACTION: The fixtures are connected to the site electrical system and can be run automatically from the building control centre. It is also possible to allow individual control of specific sections with the use of handheld remotes or enabled smartphones. Multiple uses may be achieved from single sections, such as using white light for an office during the daytime and at night using a colour changing light source to create a different ambient effect. PROJECT DURATION AND LOCATION: The project started in Sydney in May 2014 and finished in Sydney January 2015. However, there will be ongoing development to expand the capabilities of the system. FITS BEST INTO CATEGORY: Lighting Products and Fixtures Design |

PRODUCTION / REALIZATION TECHNOLOGY: A unique two part extrusion carries all components and gives access for production, installation and maintenance. The light source on the outside of the extrusion gives access to 100% of the available light. The extrusion is designed to be used as a heatsink to remove waste heat from the junction of the LED chip and PCB, thus allowing cooler operating temperature for all components. The multipurpose lens can have a clear, diffusing or opal finish SPECIFICATIONS / TECHNICAL PROPERTIES: Product dimensions: L: Variable to 4000mm, W: 80mm, H: 124mm. As each system is project specific, there is no formal packaging and on completion is packed for safety and protection for transport to site. The specifier can nominate the finish of the extrusion to any feasible colour, while the addition of light management films and different light sources can various effects. The additional use of movement and lighting level sensors can provide energy savings when not in direct use. TAGS: LED, lighting, visible light communication, extrusion, light management RESEARCH ABSTRACT: Thermal design of the extrusion/heatsink is critical to success when using higher powered LED chips. CFD software was used to model thermal flows to allow for operation in higher ambient temperatures. The lens has been created using special optical design software, particularly for the prisms on the inside at the horizontal plane. This allows a small amount of light to be directed upward, which reduces the contrast between the bright light source and the dark area above the top of the extrusion CHALLENGE: To envision a totally new system based on the potential of multiple capabilities using rapidly changing and developing technology. New components are released approximately every six months and the base platform should be able to adjust with the new technology. Emerging technology such as VLC (visible light communication) can be added to provide secure data up and download for smartphones and laptops. This can also be used in areas such as hospitals, retail and museums. ADDED DATE: 2015-02-06 01:05:52 TEAM MEMBERS (1) : IMAGE CREDITS: Bryan Liebowitz, 2014. |

||||

| Visit the following page to learn more: http://www.neolux.net.au | |||||

| AWARD DETAILS | |

|

Proteus Lighting by Bryan Liebowitz is Winner in Lighting Products and Fixtures Design Category, 2014 - 2015.· Read the interview with designer Bryan Liebowitz for design Proteus here.· Press Members: Login or Register to request an exclusive interview with Bryan Liebowitz. · Click here to register inorder to view the profile and other works by Bryan Liebowitz. |

| SOCIAL |

| + Add to Likes / Favorites | Send to My Email | Comment | Testimonials | View Press-Release | Press Kit |

Did you like Bryan Liebowitz's Lighting Design?

You will most likely enjoy other award winning lighting design as well.

Click here to view more Award Winning Lighting Design.