Cellular Table Coffee Table by Onur Ozkaya |

Home > Winners > #38478 |

|

|

||||

| DESIGN DETAILS | |||||

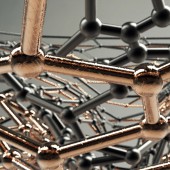

| DESIGN NAME: Cellular Table PRIMARY FUNCTION: Coffee Table INSPIRATION: Geometrical properties of liquid materials and their behaviours under certain physical conditions. UNIQUE PROPERTIES / PROJECT DESCRIPTION: Cellular Table has been developed using three different layers of cellular structure to provide both lightweight and strong result. Each layer has a different thickness in order to save material waste, aiming to create a spatial environment by providing various shadow qualities at different times of the day. The top part is made of glass and the bottom structural layers are made from three ABS plastic that 3D printed and hand-finished later to support both visual and structural performance. OPERATION / FLOW / INTERACTION: Cellular Table is super-lightweight furniture prototype that actually offers both users and fabricators to push today's contemporary manufacturing and design methods to offer much more resourceful products that also offer unexpected and exciting conditions. PROJECT DURATION AND LOCATION: The project started in June 2014 and was completed in January 2015 in London. |

PRODUCTION / REALIZATION TECHNOLOGY: 3d printing with ABS material and Electro-forming process to cover both inside and outside layers with different colour coating. SPECIFICATIONS / TECHNICAL PROPERTIES: Width 300 mm x Depth 300 mm x Height 250 mm, the cellular table is currently one option that uses two different colours: black and copper metallic electro-formed coat outside. TAGS: coffee, table, industrial, design, lightweight RESEARCH ABSTRACT: The final form has been developed using different scale lightweight models to test various options under different physical conditions. These earlier test prototypes lead to a much more precise CAD models to evaluate both structural stability and environmental conditions. CHALLENGE: The fabrication phase has been developed with two different digital fabrication facilities in London and Switzerland where they experiment on both fabrication and electroforming process. Several CAD models have been refined with the help of an engineer to evaluate certain structural conditions. During this process, both material thickness and pattern algorithm has been adjusted in order to provide much more structural stability without using too much material. ADDED DATE: 2015-01-29 17:00:18 TEAM MEMBERS (1) : Onur Ozkaya IMAGE CREDITS: Onur Ozkaya |

||||

| Visit the following page to learn more: http://bit.ly/1CVFnJ4 | |||||

| AWARD DETAILS | |

|

Cellular Table Coffee Table by Onur Ozkaya is Winner in 3D Printed Forms and Products Design Category, 2014 - 2015.· Press Members: Login or Register to request an exclusive interview with Onur Ozkaya. · Click here to register inorder to view the profile and other works by Onur Ozkaya. |

| SOCIAL |

| + Add to Likes / Favorites | Send to My Email | Comment | Testimonials | View Press-Release | Press Kit |