lasso Decorative Textile by Cristina Orozco Cuevas |

Home > Winners > #30204 |

|

|

||||

| DESIGN DETAILS | |||||

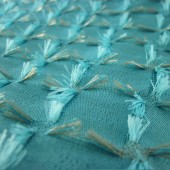

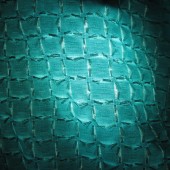

| DESIGN NAME: lasso PRIMARY FUNCTION: Decorative Textile INSPIRATION: I named it lasso as a long rope with a running noose at one end. This project can be described as: experimentation. This fabric started with the research of something very different from the result. More than inspiration this project is about having luck, stumbling upon, chance discovery, fortuity and accident. It is a piece of hard work, research, mulish and not withdraw. UNIQUE PROPERTIES / PROJECT DESCRIPTION: half industrial - half crafted, designed with textile CAD software, woven in jacquard electronic looms and cut by hand. It is woven industrially, but cut by hand which gives job to machines and external people. It forms vertical channels as a kind of fray where the light can pass through very sofltly. The frays are crafted processes and lasts months. A fabric with this kind of processes in the industry mills is nearly impossible but not that much. OPERATION / FLOW / INTERACTION: It has a special appearance as it seems as an extra application or embroidery upon the fabric but in fact it is woven like that. People always want to touch first than see the furry yarns. If there is light behind the soft feeling is quite special and light passes through the frayed parts. This kind of textile can replace goose feathers. PROJECT DURATION AND LOCATION: The project started in March, 2012 and ended in September, 2012. |

PRODUCTION / REALIZATION TECHNOLOGY: All polyester dyed yarns woven in Jacquard electronic looms. The floated yarns are cut manually by a special tool we call knife shutter. The weave technique is very old (double fabric). However the important aspect is how I applied the weaves interlaced in order to be viable to be produced and not just as a prototype as good productivity performance. The special tool developed reminded textile engineers old techniques to make corduroy. SPECIFICATIONS / TECHNICAL PROPERTIES: Widths available: 1.40 m and 2.80 m. Rapport repeat: 35 cm width x 25 cm height. Uses: lamps, pillows, bedscarfs and decorative curtains. As a finish ironing the loose fur brings more volume and the frayed channels are more obvious. It is of massive production and the loose yarns are strongly moored with a tafeta special weave union. TAGS: Jacquard, textile, decoration, fabric, lasso, half indusrtrial, half handmade, fur RESEARCH ABSTRACT: The research was completely experimental. Textile engineers were afraid that using this technique on industrial looms could not work, specially the machines weaving. The process of cutting the loose yarns was hard in order to bring a product that because of the hand crafted process would not be so expensive that would not work with the market prices. Besides the lead time to deliver a roll of this product within 3 weeks at least. Since warping process till the client's door. The cut part can be done by external workers so other people get a job. CHALLENGE: At the beginning the aim was to develop a fabric with square bags. It would have little bags to put inside tools or jewelry. After weaving and testing different techiques, this came up as a serendipity all of it. There were more than 10 previews designs to get to the final lasso fabric. The weaves interaction result was floats in warp and weft. To cut the yarns in vertical and horizontal, we developed a special tool that works as a long shuttle knife to have a better and faster production. It was an enormous challenge to have it accomplished as a product and to convince the mill that it would work. ADDED DATE: 2013-09-19 11:25:31 TEAM MEMBERS (1) : Cristina Orozco Cuevas IMAGE CREDITS: Cristina Orozco Cuevas, 2013. |

||||

| Visit the following page to learn more: http://http//:www.cristinaorozcocuevas.c |

|||||

| AWARD DETAILS | |

|

Lasso Decorative Textile by Cristina Orozco Cuevas is Winner in Textile, Fabric, Textures, Patterns and Cloth Design Category, 2013 - 2014.· Press Members: Login or Register to request an exclusive interview with Cristina Orozco Cuevas. · Click here to register inorder to view the profile and other works by Cristina Orozco Cuevas. |

| SOCIAL |

| + Add to Likes / Favorites | Send to My Email | Comment | Testimonials | View Press-Release | Press Kit | Translations |