Opx2 Optic Installation by Jonathon Anderson |

Home > Winners > #29232 |

|

|

||||

| DESIGN DETAILS | |||||

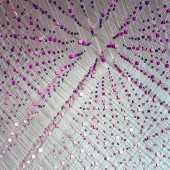

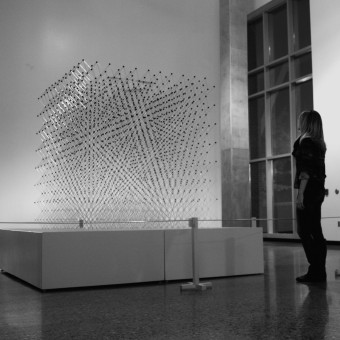

| DESIGN NAME: Opx2 PRIMARY FUNCTION: Optic Installation INSPIRATION: Opx2 explores a symbiotic relationship between nature and technology. A relationship where patterns, repetition, and rhythm describe both natural formations and operations of computing processes. The installations reclusive geometry, momentary opacity and/or density are similar to the phenomenon of driving by a cornfield or explained in technology while looking at binary code. UNIQUE PROPERTIES / PROJECT DESCRIPTION: OPX2 is made of 8000 aluminum rods 15cm in length and 1.5mm in diameter. 3D printing technology was used to fabricate each of the 2000 connections making it possible to aggregate the structure by holding each rod at an exact angle. The modularity of parts allows for Opx2 to expand and contract to any size. The photos represent a structure that is 2m x 2m x 2m and assembled with a violet gradient of connection parts. OPERATION / FLOW / INTERACTION: OPX2 is meant to be viewed from afar and up close. As you move around the structure you will notice the movement and density of the installation, this is formed by the repeated patterns and scale of materials. Each viewpoint provides a new experience where reclusive geometries begin to emerge. PROJECT DURATION AND LOCATION: Installed at the Center for Visual Artists, Greensboro, North Carolina, USA FITS BEST INTO CATEGORY: Fine Arts and Art Installation Design |

PRODUCTION / REALIZATION TECHNOLOGY: 3d printing gypsum powder, aluminum welding rods SPECIFICATIONS / TECHNICAL PROPERTIES: 2m x 2m x 2m aluminum rods are 15cm in length and 1.5mm in diameter connections are 12mm x12mm x 12mm TAGS: installation, 3d printing, technology, nature, optic RESEARCH ABSTRACT: Opx2 explores two relatively simple parts, a 3d printed connection and an aluminum rod, in order to build complex geometry which challenges ones perception of volume and space. The results are delicate in appearance and supported by using triangulation or space-frame technology to build strength while maintaining a lightweight appearance. CHALLENGE: The biggest challenge was assembling the structure even though each of the rods and connections were the same size and very accurate in geometry. A margin of error makes various portions of the installation seem loose fitting while causing others to be in extreme tension. The challenge was overcome by using paperclips with rubber bands, which held the connections together. Once the structure was fully assembled we were able to remove the rubber bands and have the installation remain structurally sound. ADDED DATE: 2013-05-19 07:12:15 TEAM MEMBERS (2) : jonathon anderson and matthew jones IMAGE CREDITS: Jonathon Anderson , 2013. |

||||

| Visit the following page to learn more: http://jonathonanderson.com/ | |||||

| AWARD DETAILS | |

|

Opx2 Optic Installation by Jonathon Anderson is Winner in Fine Arts and Art Installation Design Category, 2013 - 2014.· Press Members: Login or Register to request an exclusive interview with Jonathon Anderson . · Click here to register inorder to view the profile and other works by Jonathon Anderson . |

| SOCIAL |

| + Add to Likes / Favorites | Send to My Email | Comment | Testimonials | View Press-Release | Press Kit | Translations |