DESIGN NAME:

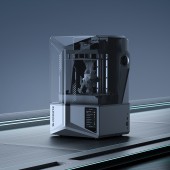

Saturn 4 Ultra

PRIMARY FUNCTION:

UV Photocuring 3D Printer

INSPIRATION:

The inspiration for the UV Photocuring 3D Printer stemmed from a desire to revolutionize traditional manufacturing processes and empower creators with innovative technology. Motivated by the limitations of conventional 3D printing methods, such as slow printing speeds and limited material options, the team sought to develop a solution that would offer faster production times, greater material versatility, and enhanced print quality.

UNIQUE PROPERTIES / PROJECT DESCRIPTION:

Saturn 4 Ultra stands out globally as an intelligent and high-speed 3D printer, combining a focus on aesthetic design with practical features. Packed with numerous cutting-edge features, including AI-assisted rapid printing, automatic leveling, power-off resume printing, material shortage alerts, and comprehensive self-detection capabilities, this printer is at the forefront of technological innovation.

OPERATION / FLOW / INTERACTION:

The fully automatic leveling function eliminates the need for customers to engage in tedious manual leveling, the machine is ready for use upon startup. In comparison to printers requiring manual leveling, the operation is more straightforward.

PROJECT DURATION AND LOCATION:

The project started in November 2023 in Shenzhen.

FITS BEST INTO CATEGORY:

Computer Graphics, 3D Modeling, Texturing, and Rendering Design

|

PRODUCTION / REALIZATION TECHNOLOGY:

As the world's first UV-curing 3D printer to incorporate AI detection, it ensures a high success rate throughout the printing process. Utilizing AI cameras and WiFi cluster printing technology, Saturn 4 Ultra provides real-time monitoring of the printing process, enabling multi-device synchronization and collaboration. These advanced features allow Saturn 4 Ultra to effectively meet users' design validation and model printing needs in various scenarios worldwide.

SPECIFICATIONS / TECHNICAL PROPERTIES:

Machine dimensions:327.4*329.2*548mm

Packaging dimensions:640*410*460mm

TAGS:

innovative,intelligent,user-friendly

RESEARCH ABSTRACT:

The product's casing is constructed from a combination of metal and recyclable copolymer materials (ABS & PC), rendering it environmentally friendly. The entire unit has obtained ROHS certification and has been recognized by multiple countries, including CE, UKCA, FCC, among others. The overall material recyclability rate exceeds 98%, and the materials are biodegradable, non-toxic, and odorless, meeting environmental standards and aligning with the sustainable development principles of green and healthy living.

CHALLENGE:

The most challenging aspect of the UV Photocuring 3D Printer was optimizing the printing process to achieve high-quality prints while balancing speed and material compatibility. Creatively, the team had to overcome obstacles related to fine-tuning the curing parameters, selecting suitable resin formulations, and designing efficient printing algorithms.

ADDED DATE:

2024-02-23 06:49:26

TEAM MEMBERS (1) :

Zhang Shengzhe,Liu Biao,Wang Jiuliang

IMAGE CREDITS:

Designer:Zhang Shengzhe,Liu Biao,Wang Jiuliang

|