DESIGN NAME:

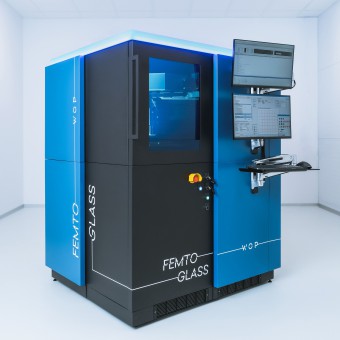

FemtoGlass

PRIMARY FUNCTION:

Glass Cutting and Dicing Workstation

INSPIRATION:

Our design team drew inspiration from the intersection of classical forms to create a unique workstation. The main body of the product embodies the elegance of a black cube, adorned with a sleek blue coat. All buttons and controls are conveniently positioned at the user's fingertips, providing effortless control and management of the cutting process. The workstation features screens and a captivating blue glass window, enhancing ease of use and visibility.

UNIQUE PROPERTIES / PROJECT DESCRIPTION:

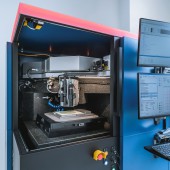

The FemtoGLASS is an advanced glass and sapphire laser cutting and dicing workstation designed for both research and development purposes, as well as high-volume manufacturing. With its unique and user-friendly access to the working areas, the FemtoGLASS offers unparalleled convenience for uploading and changing production. The workstation features an elegant LED header at the top, replacing the standard machinery traffic light, which intuitively communicates the current status.

OPERATION / FLOW / INTERACTION:

At the heart of this cutting-edge technology is patented WOP glass and sapphire cutting technology, renowned for its exceptional precision and ultra-high quality results. The FemtoGLASS is the ultimate solution for achieving superior cutting and dicing performance in the glass and sapphire industry.

PROJECT DURATION AND LOCATION:

The project began in early 2022 in Vilnius, Lithuania, with a focus on defining key technological and usability aspects. The design solution was developed in mid-2022, followed by engineering and manufacturing preparations. By the end of that year, a primary prototype was constructed and tested to ensure compliance with requirements. In early 2023, the FemtoGlass workstation was successfully released to the market.

|

PRODUCTION / REALIZATION TECHNOLOGY:

The FemtoGLASS features a semi-matt sheet metal casing, allowing for dimensional flexibility and customization based on market demand. The interior table is made of ultrastable high-quality granite, providing excellent stability and insulation against vibrations. Its main applications include glass wafer dicing, thin glass cutting, and various cutting needs for mobile phone screens, buttons, camera lenses, smart glasses, and micro-optics. With its patented glass and sapphire cutting technology, FemtoGLASS achieves ultra-high quality and precision on tempered and non-tempered glass, as well as sapphire, with minimal chipping and no post-processing required. It excels in industries like semiconductors, microfluidics, and micro-optics, enhancing glass bending strength and sidewall cut-finish quality. Notably, FemtoGLASS can cut ultra-thin glass up to 2mm in a single pass. Integrated beam stabilization and metrology solutions ensure consistent cutting accuracy and workflow efficiency, accommodating different substrate thicknesses for optimal results across applications.

SPECIFICATIONS / TECHNICAL PROPERTIES:

Main features:

Ultra-thin (30 µm to 2 mm in a single pass) glass & sapphire cutting with high process speed - up to 800 mm/s. The workstation can cut all shapes: circular, square, irregular. Tunable dicing process for different substrate thicknesses for inner and outer contours. Easy breaking for non-tempered glass and self-breaking for tempered glass

TAGS:

Workstation, wophotonics, laser, machine, industrial, glass, cutting, dicing, sapphire, manufacturing

RESEARCH ABSTRACT:

The name FemtoGLASS perfectly conveys its purpose. As the demand for precision laser dicing of brittle materials continues to grow - this solution addresses these challenges. State-of-the-art glass and sapphire cutting & dicing technology sets new standards, enhancing process yield and efficiency. This technology surpasses other glass-cutting methods, making it highly applicable in the semiconductor, microfluidics, and micro-optics industries.

CHALLENGE:

Due to the high competition in the market, the main creative challenge was to design an aesthetic laser cutting workstation, which would be minimal and understandable with unobtrusive form and standout look at the same time. The main goal was to improve the usage scenario and increase working area, without compromising the outlook and usability. The idea for the workstation was to be trustworthy, sturdy, elegant and modern with clear design language and friendly usage.

ADDED DATE:

2023-06-27 13:07:23

TEAM MEMBERS (3) :

Design: Desdorp (Deividas Juozulynas, Denis Orlenok), Technical Solution: Altechna R&D and Sheet Metals: Vaidas Paškevičius

IMAGE CREDITS:

Workshop of Photonics

|