DESIGN NAME:

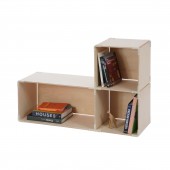

BoBoX

PRIMARY FUNCTION:

Modular Storage System

INSPIRATION:

The BoBoX project was born out of the need for a simple storage solution with a minimum number of structural and connecting elements that could be easily mounted and dismounted without installation tools, giving endless design combinations and manufactured from lightweight and sustainable materials. It is designed for residential interiors, offices, students' camps, and other public spaces.

UNIQUE PROPERTIES / PROJECT DESCRIPTION:

BoBoX is a modular lightweight storage system adapted to the needs of the flexible and dynamic urban lifestyle. The minimal do-it-yourself design uses a small set of extra thin and extra durable structural elements which offer a wide range of combinations and a playful user experience, minimizing resource use and offering greater value for the user.

Multifunctional connecting elements secure the joints and ensure the possibility of mounting a door or back panel at each box. They can be easily added at any moment after mounting, or their position can be changed.

The assembly and disassembly of the BoBoX modular storage system is tool-free.

OPERATION / FLOW / INTERACTION:

The storage system provides easy and reliable assembly of structures with any number of modules in length and height. Multifunctional connecting elements made of highly-durable bio-based PLA, secure the joints of extra thin plywood panels. Inserting additional simple functional element on top of the connector makes it possible to mount a hinged door, flap door or back panel. For extra functionality of the storage system, due a developed innovative connecting system, doors and back panels can be installed and removed at any time without the need to dismantle the entire furniture.

The assembly and disassembly of the modular constructions is tool-free.

PROJECT DURATION AND LOCATION:

The project started in June 2020 and finished in April 2021 in Sofia.

The project was shown at Grand Prix Du Design in October 2021 and win Platinum Award

FITS BEST INTO CATEGORY:

Furniture Design

|

PRODUCTION / REALIZATION TECHNOLOGY:

The modular system is manufactured from 9mm birch plywood in two versions - natural and laminated. In the first version the plywood is waxed, and in the other it is laminated with soft touch HPL, which is smooth, highly resistant to scratches and heat, as well as being anti-fingerprint. The 3D printed connectors and functional elements made of highly-durable bio-based PLA.

SPECIFICATIONS / TECHNICAL PROPERTIES:

BoBoX storage system is composed of only 2 types of structural elements - extra thin birch plywood panels (9 mm) or birch plywood laminated with soft touch HPL (10.8 mm) and 3D printed multifunctional connectors. The wood-based panels come in 320 x 320 mm and 320 x 640 mm and the L, T and X-shaped innovative connectors secure the joints between them.

The connectors are transformed with the help of 4 additional elements which improve the functionality of the system by adding hinge doors, flap doors and back panels. Doors and back panels have the dimensions of 303x303 and 303 x 623 mm.

The system provides flat packing.

TAGS:

BoBoX, BoBoX Storage System, DIY Dynamic Storage System, Modular Storage Furniture, Flatpack System, Multifunctional Connecting Elements, Do-it-Yourself Design, Furniture Design, 3D Printing design, Lightweight Furniture Design

RESEARCH ABSTRACT:

BoBoX was created after significant preliminary research, experiments and prototyping. The mechanical properties were established of different materials – birch and beech plywood, natural and laminated MDF and laminated particleboards. For creating a BoBoX concept, a 9 mm birch plywood was selected in two versions - natural and HPL-laminated, which showed the highest bending strength and modulus of elasticity with an excellent ratio of strength-weight.

The same approach was followed in the development of the multifunctional connectors. Tests were carried out on corner joints with different length, width and thickness parameters of the connectors to establish their optimum shape and size. Prototypes of BoBoX concept were developed with different bio-plastic materials and colour combinations of 3D printing printed elements and HPL.

CHALLENGE:

The challenges in developing this project were:

to allow creation of storage furniture without limitation in length and height of the composition; to be able to construct furniture from thin and ultra-thin wood-based materials; to provide interchangeability of structural elements - bottom, top and side panels; assembly and disassembly to be carried out without the need for special skills and tools; to be able to easily and quickly dismantle and reassemble the constructed furniture in order to move and use it elsewhere; in disassembled form, the constructions should be compact and small in volume to reduce transport and storage costs; to be able to insert and remove doors and back panels at any time and at any arbitrarily selected volume without the need to disassemble and reassemble the structure; users to be able to change the composition of boxes at any time during operation; the joints can also be used as legs of the cabinet furniture; ensure that the different types of materials can be separated at the end of the furniture's life cycle for reuse or recycling.

ADDED DATE:

2022-02-26 05:36:40

TEAM MEMBERS (2) :

Boryana Petrova and Vassil Jivkov

IMAGE CREDITS:

Boryana Petrova and Vassil Jivkov, 2021.

PATENTS/COPYRIGHTS:

IP Public RCDs 008752760-0001, EIUPO

Locarno class 06.04

|