DESIGN NAME:

Nave

PRIMARY FUNCTION:

Air Conditioning System

INSPIRATION:

The motive for the project was the idea that the walls in the space can become active- benefits the people who live in the space.

The main inspiration was the work of Egyptian architect Hassan Fathy, who pioneered the use of traditional building methods to design local oriented buildings.

The cooling method in the project is based on the Palastinian Jara- a traditional terracotta water container that was hung from the ceiling of the room. It was used to cool drinking water and chill the room.

UNIQUE PROPERTIES / PROJECT DESCRIPTION:

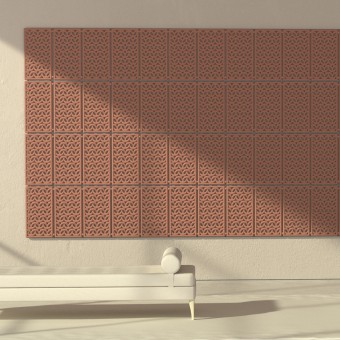

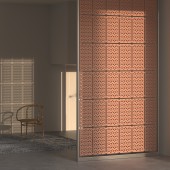

NAVE is a terracotta tile system combined with water flow, used to cool indoor spaces in desertic environments.

The cooling method is based on a local traditional cooling solution, and answers a local need.

In the project,The tile transforms form a generic product, back into a local, tailored to place product.

The system operates on minimal energy and water consumption and is used for green building.

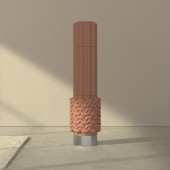

The system has three variations: Wall tiles, Partition and a totem- vertical cooling body.

OPERATION / FLOW / INTERACTION:

On a day to day use, there is almost no interaction between the user and the system. The system is automatic and autonomic, and fully controlled by an irrigation system to keep the space in a constant state of climate comfort.

The user has the option to pause, shut down or reprogram the temperature and humidity goal.

The assembly system for Nave was designed based on existing mounting solutions from the construction world. Acquaintance with the method and tools of assembly will ease the use of this new product for architects, contractors and builders, and encourage them to choose the sustainable solution over the existing one.

PROJECT DURATION AND LOCATION:

The project started in October 2019, and presented as a thesis project in September 2020. The design development was made in Tel Aviv, Israel, and the project is destined to the Negev area, Israel.

FITS BEST INTO CATEGORY:

Building Materials and Construction Components Design

|

PRODUCTION / REALIZATION TECHNOLOGY:

All of the ceramic bodies are hollow bodies of local terracotta, manufactured with plaster molds in slip casting technology.

A dedicated formula controls the irrigation of the system, optimizes temperature, water use and humidity, and prevents mold formation.

The flexible joints are made by injection molding of recycled rubber.

SPECIFICATIONS / TECHNICAL PROPERTIES:

Each wall/partition tile is 250mm x 15 mm x 500mm, with the surface of 3820 cm² to maximize efficiency.

The tiles are assembled using steel rulers, in a method similar to roof tiles assembly.

The partition tiles are assembled on steel wires with added metal rules, and the “totem” bodies are stacked surrounding a metal spine.

TAGS:

Green building, Terracotta, Local design, Cooling system, Traditional design, Ceramics

RESEARCH ABSTRACT:

The technical research for “Nave” consisted of 3 main steps:

The first step’s objective was identifying a cooling principle that can be used in a tile format,is matching with the environmental conditions of the desert and is energy efficient.

This part of the research was conducted as exploring existing cooling solutions: Cooling mechanisms in plants and animals, traditional cooling solutions and desertic architecture, and new materials and inventions. The conclusion was that the traditional cooling solution (water flow in a terracotta vessel) is actually the most fitting to the desertic environment. This conclusion came with an insite, that traditional solutions could be renovated to solve contemporary problems, and that they are, by nature, lean in energy and resources - hence more sustainable.

The second step’s objective was to sanitize the cooling principle into a formula that will be able to calculate the amount of water needed for the system in any given space size, temperature and humidity percentage. This step was essential to create a controlled, functional system, avoid overuse of water and the creation of mold.This part of the research was a combination of “material research” that consisted of experiments with terracotta tiles in different shapes and a development of the irrigation formula developed by a physicist. In the experiments, a wet ceramic tile was placed in a container simulating a desertic climate. In each experiment a different kind of tile was put (different in thickness, size, or shape). The results of the experiments helped establish how the tile’s thickness and its surface size and shape influence the efficiency of the water evaporation, and provided data on the tile’s influence on temperature and humidity change in a space over time.

Lastly, along with designing the tiles shape and look (with the desired surface) arose the need to design an efficient and approachable method of assembly. That objective was crucial, because comfort, time effectiveness, cost and flexibility would be crucial to the application of the system in the “real-world” and the appeal to the professionals involved in the purchase and installation of the system. The research consisted of a lot of interviews with different professionals from the construction word, from architects to plumbers. It concluded with the design of the assembly system based on existing principles from the construction world (methods of roof tiling for example).

CHALLENGE:

The major technical/research challenge in the development of “Nave” was transforming an uncontrollable cooling principle (a combination of water and terracotta, both natural materials) to a controlled cooling system. This was crucial. The system has to be extremely comfortable in order to be appealing as a cooling solution, and has to be very accurate in the amounts of water coming in the system, to not be wasteful and not cause damage.I have mastered the issue by exploring many directions for inspirations and consulting with people wiser than myself. I had the assistance of a very talented physicist (Yuval Bashan). We combined the results of the experiments I had conducted (mentioned before) and his knowledge, to develop the irrigation formula.

I solved the challenge of the shape using 2 principles: First, Provide several options of shape. The belonging of the product to the “tile” product category, made it sensible to offer several shape options and variations.

Second, I searched for a pattern that belongs to the semantic image world of “cooling”.

I developed 2 main patterns ; “cooling ribs” pattern, belongs to the image world of radiators and electric components, and a “‘weaved” pattern, inspired by traditional weaved partitions, made to provide shape and allow air flow in spaces in desertic environments.

ADDED DATE:

2021-06-24 14:19:51

TEAM MEMBERS (1) :

IMAGE CREDITS:

Images #1,#3,#4,#5 : CGI Artist Francesco Maria Lucini, 2020

Images #2: Noa Paul, 2020

PATENTS/COPYRIGHTS:

Copyrights belong to Yael Issacharov, 2020

|