FlowIO Pneumatics Development Platform by Ali Shtarbanov |

Home > Winners > #122452 |

|

|

||||

| DESIGN DETAILS | |||||

| DESIGN NAME: FlowIO PRIMARY FUNCTION: Pneumatics Development Platform INSPIRATION: Arduino and Raspberry Pi democratized electronics and computing. FlowIO aims to democratize soft robotics and programmable materials in a similar way. The lack of development platforms for soft robotics makes the field highly inaccessible for most people and stifles innovation. The FlowIO platform was developed with the goal to democratized the emerging field of soft robotics and make rapid prototyping more accessible for researchers, artists, designers, and makers. UNIQUE PROPERTIES / PROJECT DESCRIPTION: FlowIO is a fully-integrated, general-purpose development platform for control of soft robots and programmable materials. With magnetically connected pump modules that are swappable on-the-fly, FlowIO can satisfy diverse project needs of researchers, artists, and makers. A software toolkit with mobile and desktop graphical interfaces, Bluetooth controls, and APIs for Arduino and JavaScript — enable users from any technical background to get started and unleash their creativity with FlowIO. OPERATION / FLOW / INTERACTION: FlowIO enables users to rapidly bring soft robotics projects to life and to focus on developing actuators and experiences instead of spending time designing pneumatics, electronics, or writing control software. Miniature size, battery operation, and various modules and accessories make FlowIO suitable for both desktop and wearable applications involving inflation, vacuum, release, pressure sense, and flow variability. Multiple APIs and GUI make it possible for anyone to use the device with ease. PROJECT DURATION AND LOCATION: FlowIO originated out of necessity as a system I made for my own research in soft robotics and morphable interfaces at MIT Media Lab. As many other researchers, makers, and artists showed strong interest and asked to use FlowIO in their own works, in late 2019 the idea was born to augment FlowIO into a truly general purpose pneumatics development platform suitable for everyone. FlowIO has now undergone over 20 prototype iterations, with numerous new features added during those iterations. |

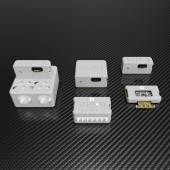

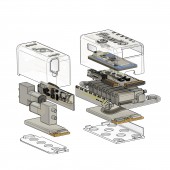

PRODUCTION / REALIZATION TECHNOLOGY: FlowIO contains a main module, different pump modules, expansion modules, and accessories. The main module integrates 7 valves, 2 custom PCBs, sensors, microcontroller, and a battery with charger. Each pump module has 2 pumps, a custom PCB, and a battery with integrated charger. Auxiliary modules also consist of custom PCBs. The modules connect magnetically and are enclosed in 3D-printed snap-fit enclosures, that can be printed in any color. All hardware designs are made public and open-source. SPECIFICATIONS / TECHNICAL PROPERTIES: Five pneumatic I/O ports, each capable of 7 actions, and three swappable pump modules (small, medium, large) can satisfy different needs for pressures (-26 to 30 psi), size, and flow-rates. FlowIO with small pumps has dimensions 59x55x28 mm and mass of only 114g. Expansion modules and accessories enable additional sensing, control, and mounting options for both wearable and nonwearable applications. BLE Capability, multiple APIs, and a GUI enable diverse options for interacting with FlowIO. TAGS: Development Platform, Toolkit, Pneumatic Control System, Soft Robotics, Programmable Materials, Shape Change, Tangible User Interface, Wearables, Arduino, Raspberry Pi RESEARCH ABSTRACT: Over a dozen people have used FlowIO to date, from PhD researchers and high-school students to makers and artists. It has enabled people to develop projects in various categories including interactivity, artistic expression, locomotion, telepresence, haptic feedback, and assistive technologies. Feedback was collected from existing and prospective users continuously to inform many of the design iterations. FlowIO was also used as a teaching tool in a graduate digital fabrication course at MIT. CHALLENGE: The main challenge was making FlowIO highly energy-efficient and miniaturized yet fully-integrated with pumps, valves, sensors, electronics, batteries. and even charging circuits. Other pneumatic platforms with far fewer capabilities are 5-10 times larger than FlowIO and they still require external pumps and/or power sources. Over a dozen design iterations were dedicated towards finding clever ways of reducing size. Developing multiple APIs and a cross-platform GUI was another major challenge. ADDED DATE: 2021-03-01 01:20:37 TEAM MEMBERS (4) : Ali Shtarbanov, Hyejun Youn, Ozgun Afsar and Advisor: Dr. Joseph Paradiso of MIT Media Lab IMAGE CREDITS: Ali Shtarbanov |

||||

| Visit the following page to learn more: http://www.softrobotics.io | |||||

| AWARD DETAILS | |

|

Flowio Pneumatics Development Platform by Ali Shtarbanov is Winner in Scientific Instruments and Research Equipment Design Category, 2020 - 2021.· Press Members: Login or Register to request an exclusive interview with Ali Shtarbanov. · Click here to register inorder to view the profile and other works by Ali Shtarbanov. |

| SOCIAL |

| + Add to Likes / Favorites | Send to My Email | Comment | Testimonials | View Press-Release | Press Kit |