DESIGN NAME:

1x1

PRIMARY FUNCTION:

Urban Furniture System

INSPIRATION:

Design derived from the inspiration of a post-industrial site Refshaleoen, Copenhagen. Due to a comprehensive understanding of the site qualities, was pointed out the concern that the site would not have an extensive public realm, thus it was retrieved to hypothetically provide it through a multitude of small interventions. Furthermore, apart from the inspiration of rich and unique site qualities, the concept was influenced by insights of scaffolding structure and Dieter Rams shelving system 606.

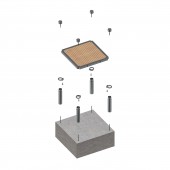

UNIQUE PROPERTIES / PROJECT DESCRIPTION:

The design is a unique modular urban furniture family. Furniture elements work both as stand-alone urban furniture pieces as well as a small scale public realm with adjustable programs. Design can be described as flexible, scalable, industrial, modular urban furniture which can work as a permanent or temporary public space intervention. Due to the intelligent use of materials design achieves high optimization as all elements use the same standardized frame structure likewise common materials and fixing methods.

OPERATION / FLOW / INTERACTION:

The system can work as individual furniture piece (bench/planter) or in groups forming small outside spaces (park/urban farm). While one might initially need only a small seating place outside their facility, another season might ask for a larger space where increasing numbers of visitors and clients could be accommodated. 1x1 design allows to expand or shrink by either adding or taking away individual elements. Furthermore, there is no need for a long-term commitment in case something changes.

PROJECT DURATION AND LOCATION:

The project is a conceptual design with design inspiration deriving from Refshaleoen, Copenhagen. Though design could be implemented and used in other sites, preferably within an industrial setting

|

PRODUCTION / REALIZATION TECHNOLOGY:

Materials:

Timber (Local or Baltic Birch)

Concrete (Precast)

Steel (Stainless Steel)

All the elements would be manufactured off-site and then brought for assembly to the site, thus optimizing the shipment size and convenience of production.

Realization Technology:

Manufacturing would be quite conventional since there is no complex geometry involved. Concrete would be precast, timber parts cut using usual machines and steel parts would be coming from semi-finished elements welded together.

SPECIFICATIONS / TECHNICAL PROPERTIES:

Bench: 1000mm x 1000mm x 460mm

Table/Platform: 1000mm x 1000mm x 60mm

Lamppost: 100mm x 100mm x 1000mm

1m. Planter: 1000mm x 1000mm x 1000mm

0.5m Planter: 1000mm x 1000mm x 500mm

1m.Pipe: 100mm x 100mm x 1040mm

0.5m. Pipe: 100mm x 100mm x 540mm

0.25m. Pipe: 100mm x 100mm x 290mm

Additional information and drawings are inside the PDF document.

TAGS:

Industrial, Modular, Scalable, Interactive, Optimized

RESEARCH ABSTRACT:

In the world, with continuous globalization and mass production, we forget to address the need for individuality. While in architecture it is a common understanding to respond to a site's specific needs and spatial qualities, street furniture is usually the victim of generic design. The industry is moving towards supply by demand model with local solutions and the customer having an increasingly higher voice in customization. 1x1 modular furniture design attempts to address these concerns

CHALLENGE:

One of the hardest challenges was how to make individual elements work together in a vertical and horizontal structure layout. Furthermore, how to minimise material options as well as fixing methods while creating a robust and feasible design proposal.

ADDED DATE:

2020-02-28 13:57:28

TEAM MEMBERS (2) :

Mykolas Seckus and Antonio Gandolfo

IMAGE CREDITS:

credits for visuals:

Antonio Gandolfo & Mykolas Seckus

|