| THE AWARD |

| CATEGORIES |

| REGISTRATION |

| SUBMIT YOUR WORK |

| ENTRY INSTRUCTIONS |

| TERMS & CONDITIONS |

| PUBLICATIONS |

| DATES & FEES |

| METHODOLOGY |

| CONTACT |

| WINNERS |

| PRESS ROOM |

| GET INVOLVED |

| DESIGN PRIZE |

| DESIGN STORE |

| THE AWARD | JURY | CATEGORIES | REGISTRATION | PRESS | WINNERS | PUBLICATIONS | ENTRY INSTRUCTIONS |

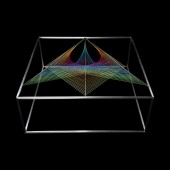

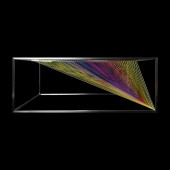

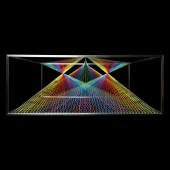

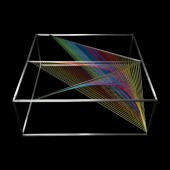

Prism Coffee Table by Maurie Novak |

Home > Winners > Design #33314 >Interview |

|

|

FS: What is the main principle, idea and inspiration behind your design?

MN: It is hard to define a single principal or idea as being behind the design of Prism. I would say that a deeper goal I have with this design and other, is a desire to create a balance between opposing concepts. Composed of a minimal frame, which holds within it a complex array of elastic, Prism's frame is created using modern technology, whilst the elastic has to be painstakingly threaded by hand. Its geometry weaves a complicated pattern which is in fact the result of only two simple equations. Its frame is silver stainless steel which radiates into a rainbow of colour. It is only by uniting these opposing ideas that Prism is able to form a balance.

FS: What has been your main focus in designing this work? Especially what did you want to achieve?

MN: My main focus in designing this piece was to completely perfect a design that I felt was worthy of being refined. I wanted to take the opportunity to take one of my designs and make sure every aspect of it works perfectly, without fault or flaw. I have conceptually designed hundreds of ideas, I have built tens of these concepts myself, but I had not until now taken one of my designs from being a one off, to being a refined manufacturable design.

FS: What are your future plans for this award winning design?

MN: I have until recently been working for others. Recently, I launched my own company and am taking on projects that I am passionate about and want to pursue. This piece of furniture is the first piece that I have had the opportunity to fully develop, and aim to find the right avenues to begin selling this piece. I am using this piece as a jumping off point for my business, hoping it will lead me to a point where I can develop further design concepts.

FS: How long did it take you to design this particular concept?

MN: I came up with the basis of this design about a year and a half ago. I left it in the conceptual stage for quite a while, just considering it and refining it before attempting to build it. It took me about six months and a few prototypes to come to the finished design.

FS: Why did you design this particular concept? Was this design commissioned or did you decide to pursuit an inspiration?

MN: Prism was designed as the pursuit of an idea. I wanted to see how I could integrate string art into a living environment in a functional way. This was my starting point - as I continued, I found lots of areas that I wanted to investigate.

FS: Is your design being produced or used by another company, or do you plan to sell or lease the production rights or do you intent to produce your work yourself?

MN: At this point I have produced a limited run of the piece myself. I am currently finding stores and galleries to display my piece. I may soon produced another lot of tables, but in the long term I will have to evaluate my options of how it is best to produce and distribute this table.

FS: What made you design this particular type of work?

MN: String art has always struck me as being quite beautiful and expressive. However it is a type of art form which in general can be appreciated either by having a two dimensional artwork on ones wall, or as an instillation piece viewed in a gallery. I wanted to take this concept, and try to give it form in a functional way, a way that one can have a large scale piece of art to appreciate, but for it to fit into an environment in a practical way.

FS: Where there any other designs and/or designers that helped the influence the design of your work?

MN: There has been a lot of string art appearing across the internet over the past few years that has proved inspirational. I would say that in particular the beautiful works of Gabriel Dawe helped to inspire the creation of Prism.

FS: Who is the target customer for his design?

MN: By virtue of the expensive and difficult production process of making this piece, Prism would be targeted at a higher end consumer. However I am aiming to develop further pieces with different production methods and materials which could be available to a wider market.

FS: What sets this design apart from other similar or resembling concepts?

MN: To be honest I have not yet come across pieces of furniture that I know of that have the same principals and complexity. I may be wrong, but as far as I know Prism stands alone in its uniqueness as a table containing a sculptural piece of this sort.

FS: How did you come up with the name for this design? What does it mean?

MN: The name Prism developed along with the design. Beginning the design process for this piece, there was a world of variability and possibility available to me. Needing to refine and set some rules by which I could design my piece, I used a prism as inspiration. A prism has a triangular form which refracts light into a rainbow of colours. This tool informed the colour choice and form of the design - leading to the name 'Prism'.

FS: Who did you collaborate with for this design? Did you work with people with technical / specialized skills?

MN: I worked with a local metal fabrication company called 'Wade Fab' to produce the steel frames for my table.

FS: What is the role of technology in this particular design?

MN: Technology plays a key role in the production of Prism. A laser cutter is used to evenly drill the 196 holes that make up this table. A CNC router is used to rout a channel into the tables frame. Without the use of these technologies the table would not be able to be produced as perfectly as it is.

FS: What are some of the challenges you faced during the design/realization of your concept?

MN: There were many challenges that I faced in the realisation of this concept. Materials, and material strength was always a challenge which almost saw this design scrapped along the way. I like to be uncompromising in the realization of a design. Having a frame that is 16mm thick, and is able to support the glass and the elastic within it was quite a challenge. Material selections for the strings was challenging, as string was just inappropriate for the project, and finding the right type and weight of elastic was not easy.

FS: How did you decide to submit your design to an international design competition?

MN: I first released images of my design on the internet, and it found its way only many design blogs. Seeing how well received it was, I decided that I may as well give it a go and enter it in this competition. The worst thing that could happen is not winning.

FS: What did you learn or how did you improve yourself during the designing of this work?

MN: I have and am still learning a lot about taking a project from a concept through to a manufactured piece - it is a challenging process which I am really grateful I have the opportunity to undertake.

FS: Thank you for providing us with this opportunity to interview you.

A' Design Award and Competitions grants rights to press members and bloggers to use parts of this interview. This interview is provided as it is; DesignPRWire and A' Design Award and Competitions cannot be held responsible for the answers given by participating designers.

| SOCIAL |

| + Add to Likes / Favorites | Send to My Email | Comment | View Press-Release | Translations |